Inventory Optimization to Make Your Supply Chain More Effective

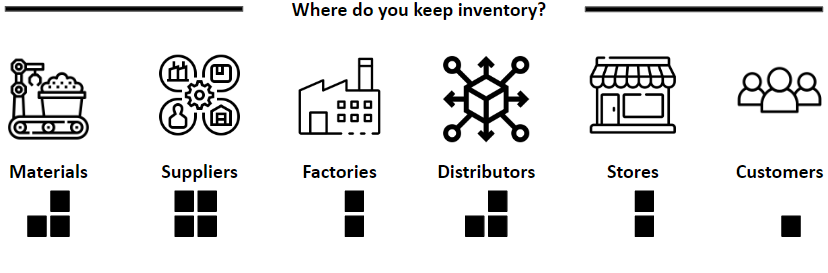

Inventory management is a complex and critical aspect of any business, encompassing raw materials, work-in-progress goods, and finished goods that can be spread across various entities in the supply chain, including vendors, suppliers, distributors, and stores. Poor inventory management can lead to a loss of revenue and dissatisfied customers, making it essential for businesses to implement effective inventory optimization strategies.

The Challenge of Inventory Management

Managing inventory is not a one-size-fits-all endeavor. Inventory policies need to consider various factors such as business objectives, changing market conditions, and supply chain constraints. These policies define what to carry in terms of inventories, their form, and quantity, across procurement, manufacturing, and distribution networks. There are both advantages and disadvantages to carrying inventory throughout the supply chain, impacting suppliers, manufacturers, transportation, distribution centers, retailers, and customers. An inventory strategy would account for the pros and cons of where to carry the inventory and ultimately optimize those tradeoffs.

The Impact of Inventory on Customer Service

Consistently delivering high service levels across multiple channels has become increasingly challenging and complex. It’s important to recognize that the relationship between inventory and customer service is not linear. Simple metrics like days of cover for inventory management may fall short. To make informed decisions, businesses need to consider both demand and supply risks where supply risks are the variability of lead times and demand risk are the forecast error. Taking these considerations into account will enable you to move beyond simple inventory management and make your operations more efficient.

Strategic and Tactical Planning

Effective inventory management involves both strategic and tactical planning. Businesses need to consider what to make, what to buy, and from whom, as well as what inventories to carry, where to carry them, in what form, and how much. An inventory optimization solution can play a pivotal role in generating optimized stock levels and inventory policies for fulfillment or master planning. It should also enable efficient modeling and data management while facilitating what-if scenarios to analyze and view the impact of inventory plans. These tools will drive further efficiencies into the process.

Benefits of Inventory Optimization

Inventory optimization is not just about short-term gains; it’s a strategic imperative that aligns inventory policies and processes with overarching business goals. Implementing inventory optimization solutions can result in the following benefits:

- Reduced operational costs: Inventory optimization software can identify slow-moving products and recommend restocking, cutting storage and warehousing expenses.

- Increased customer satisfaction: Optimized inventory ensures quicker order fulfillment and faster delivery, enhancing customer satisfaction and preventing overstocking costs.

- Improved delivery time: Inventory optimization helps track product distribution, enabling targeted stocking at high-demand warehouse locations for timely order processing and delivery.

- Optimized inventory: Precise knowledge of available SKUs in warehouses enhances inventory management, cash flow, storage space utilization, and consistent product delivery.

Your Partner for Inventory Optimization

K3 Group specializes in providing expert services to implement these inventory optimization solutions. Our capabilities span inventory strategy, tactical planning, and execution management, helping businesses streamline inventory processes, reduce operational costs, and enhance customer satisfaction. During an implementation we will:

- Implement tools that will generate optimized stock levels and inventory policies that can be used in other solutions for fulfillment or master planning.

- Use a tool that provides efficient modeling and data management.

- Give users the ability to segment key value items or problem items from other inventory.

- Provide the ability to conduct what-if scenarios so that you can analyze and view the impact of inventory plans, aiding in your decision-making.

Conclusion

In today’s efficient supply chains, inventory optimization is not just a choice; it’s a strategic imperative. Our consulting services offer tailored services to meet the demands of real-world operations, allowing businesses to reap the benefits of enhanced performance and a rapid return on investment. By enabling inventory optimization, businesses can reduce costs, enhance efficiency, and position themselves as leaders in their industries, equipped with a potent strategic advantage. K3 Group is your trusted partner on this transformative journey toward a brighter future.

Here are the other supply chain processes we support including demand planning, master planning, and fulfillment provided by our partners like BlueYonder, o9, and Kinaxis.